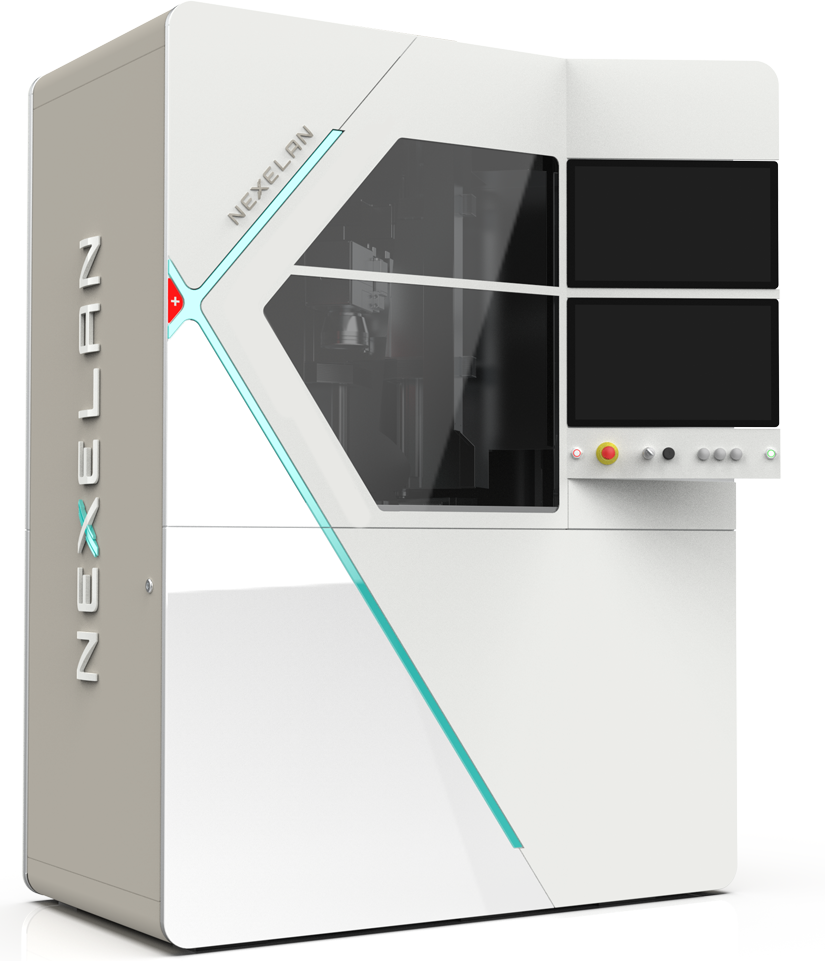

Discover the game-changing solution NEXELAN, the future for large-scale, accessible and affordable integration of USP laser systems.

- Engraving

- Ablation

- Cutting

- Automatic tool changer

- Up to 6 operations per machine

- Versatility at its best

TECprocess has taken up the challenge and presents its new NEXELAN femtosecond laser platform, a compact and versatile machine for 2D and 3D engraving, ablation and cutting.

The solution incorporates an innovative automatic tool changer that allows up to six laser machining and measurement operations to be combined on a single machine.

|

Technical Specifications |

||

|

Machine dimensions (mm) |

1'650 x 850 x 2'350 |

|

|

Machine weight (kg) |

1'800 |

|

|

Table size (mm) |

150 x 210 |

|

|

Strokes X / Y / Z (mm) |

500 x 400 x 400 |

|

|

Laser sources |

Multiple sources: |

|

|

Wavelengths (nm) |

IR 1030 / GR 515 / Hybrid 1030+515 |

|

|

Scanheads |

scanCUBE / excelliSCAN |

|

|

Optics |

Depending on RAYVOLVER configuration |

|

Typical applications of ultra-short pulse (USP) laser technology include engraving and cutting for watchmaking and jewelry parts, texturing of micro-molds for miniature optical systems, engraving and cutting in medical devices, including black-marking applications, micro-machining by laser turning, etc.

The up-coming challenge to address increasingly complex demands is combining laser technology, flexible optical setup and metrology on a single platform in order to achieve improved parts of unprecedented quality in the shortest possible time.

Your production equipment can thus evolve and adapt over time to the changing needs of your customers, offering valuable added value for all types of geometries and all types of materials and provides a unique competitive advantage to your own configuration.

The patented RAYVOLVER is the reliable and compact way to boost the productivity of your future laser equipment without compromising between quality and complexity.

The proposed solution is a novel system enabling the combination of several focusing optics, metrology tools and other devices in a single machine.

The patented RAYVOLVER is an automatic tool changer based on a high-repeatability reference clamping mechanism. It meets both the ambition for optical versatility and the need for integrated metrology by allowing optimization without human intervention and paves the way towards efficient use of the full capabilities of machines equipped with USP laser sources.

This triggers phenomenal productivity benefits by combining it all on the same machine without compromising operation simplicity or part accuracy. Resulting assets like timesaving and reliability are unique by simply eliminating risky repositioning and recalibration of semi-finished and potentially expensive parts.

The RAYVOLVER, in combination with the outstanding performance of SCANLAB scan-heads, unlocks the full potential of high-quality USP laser processing and allows product designers and production specialists to go beyond the boundaries set by conventional solutions. The implicit evolutivity of the process, starting from a simple engraving operation up to the full combination of probe-sensing, vision, ablation, cutting, texturing, finishing, quality control, handling, etc. enables total process control over the whole machine life-cycle. Discover the game-changing solution NEXELAN, the future for large-scale, accessible and affordable integration of USP laser systems.